- 您现在的位置:买卖IC网 > Sheet目录1 > 333-2UYC/S530-A3 (Everlight Electronics Co Ltd)LED 5MM SUPER YELLOW CLEAR RND

DATASHEET

LAMP

333-2UYC/S530-A3

6

Copyright ?2010, Everlight All Rights Reserved. Release Date : Nov.07. 2013. Issue No: DLE-0006195_Rev.6

www.everlight.com

Prehead

laminar wave

Fluxing

otes

1. Lead Forming

During lead formation, the leads should be bent at a point at least 3mm from the base of the epoxy bulb.

Lead forming should be done before soldering.

Avoid stressing the LED package during leads forming. The stress to the base may damage the LEDs characteristics or it

may break the LEDs.

Cut the LED lead frames at room temperature. Cutting the lead frames at high temperatures may cause failure of the LEDs.

When mounting the LEDs onto a PCB, the PCB holes must be aligned exactly with the lead position of the LED. If the LEDs

are mounted with stress at the leads, it causes deterioration of the epoxy resin and this will degrade the LEDs.

2. Storage

The LEDs should be stored at 30?C or less and 70%RH or less after being shipped from Everlight and the storage life limits

are 3 months. If the LEDs are stored for 3 months or more, they can be stored for a year in a sealed container with a

nitrogen atmosphere and moisture absorbent material.

Please avoid rapid transitions in ambient temperature, especially, in high humidity environments where condensation can

occur.

3. Soldering

Careful attention should be paid during soldering. When soldering, leave more then 3mm from solder joint to epoxy bulb,

and soldering beyond the base of the tie bar is recommended.

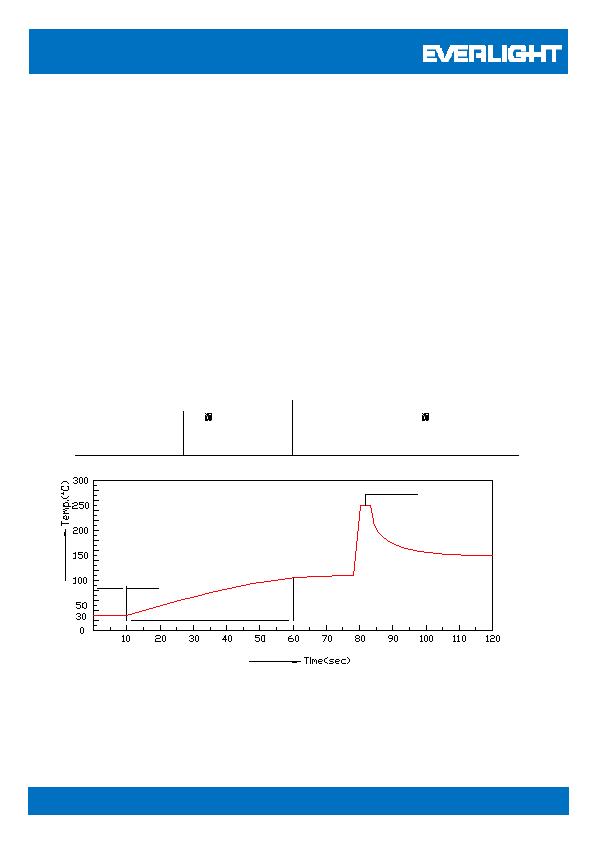

Recommended soldering conditions:

Hand Soldering

DIP Soldering

Temp. at tip of iron

300

Max. (30W Max.)

Preheat temp.

100

Max. (60 sec Max.)

Soldering time

3 sec Max.

Bath temp. & time

260 Max., 5 sec Max

Distance

3mm Min.(From solder

joint to epoxy bulb)

Distance

3mm Min. (From solder

joint to epoxy bulb)

Recommended soldering profile

Avoiding applying any stress to the lead frame while the LEDs are at high temperature particularly when soldering.

Dip and hand soldering should not be done more than one time

After soldering the LEDs, the epoxy bulb should be protected from mechanical shock or vibration until the LEDs return to

room temperature.

A rapid-rate process is not recommended for cooling the LEDs down from the peak temperature.

发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

333-2UYD/S530-A3

LED 5MM SUPER YELLOW DIFF RND

334-15/T2C1-1UWA

LED 5MM WHITE WATER CLEAR ROUND

383-2UYC/S400-A6

LED 5MM SUPER YELLOW WATER CLEAR

4300F5LC

LED GREEN BRITE T-1

4300H5LC

LED BRITE GREEN T1-3/4 LOW CURR

4301F11/17

LED T-1 RED/YELLOW WHT DIFF TH

4301H1/1

LED T1-3/4 RED/RED DIFF TH

4301H1/5-TA1

LED T1-3/4 RED/GREEN DIFF TH

相关代理商/技术参数

333-2UYC/S530-A4

功能描述:标准LED-通孔 Super Yellow RoHS:否 制造商:Vishay Semiconductors 照明颜色:Red 光强度:0.7 mcd 波长/色温:615 nm 显示角:45 deg 透镜颜色/类型:Clear, Non-Diffused 正向电流:70 mA 正向电压:1.83 V to 3.03 V LED 大小:2 mm 系列: 封装:Tube

333-2UYC/S530-A5

功能描述:标准LED-通孔 Super Yellow RoHS:否 制造商:Vishay Semiconductors 照明颜色:Red 光强度:0.7 mcd 波长/色温:615 nm 显示角:45 deg 透镜颜色/类型:Clear, Non-Diffused 正向电流:70 mA 正向电压:1.83 V to 3.03 V LED 大小:2 mm 系列: 封装:Tube

333-2UYC/S530-A6

制造商:Everlight Electronics Co 功能描述:

333-2UYC-H3

制造商:EVERLIGHT 制造商全称:Everlight Electronics Co., Ltd 功能描述:5.0mm Round Type LED Lamps

333-2UYC-S400

制造商:EVERLIGHT 制造商全称:Everlight Electronics Co., Ltd 功能描述:5.0mm Round Type LED Lamps

333-2UYC-S400-A4

制造商:EVERLIGHT 制造商全称:Everlight Electronics Co., Ltd 功能描述:5.0mm Round Type LED Lamps

333-2UYC-S400-A7

制造商:EVERLIGHT 制造商全称:Everlight Electronics Co., Ltd 功能描述:5.0mm Round Type LED Lamps

333-2UYC-S530

制造商:EVERLIGHT 制造商全称:Everlight Electronics Co., Ltd 功能描述:5.0mm Round Type LED Lamps